Zinc recycling involves the recovery and reuse of Zinc from various recyclable materials, such as scrap metal, galvanized products, or zinc-containing industrial by-products. The recycling of Zinc is crucial for environmental sustainability, as it reduces the need for mining and minimizes waste. Zinc is often used in the galvanization process, where it is coated onto steel or iron to prevent rust. The recycling of Zinc also allows the production of high-purity Zinc oxide, a valuable chemical used in various industries, including rubber, paint, and medicine.

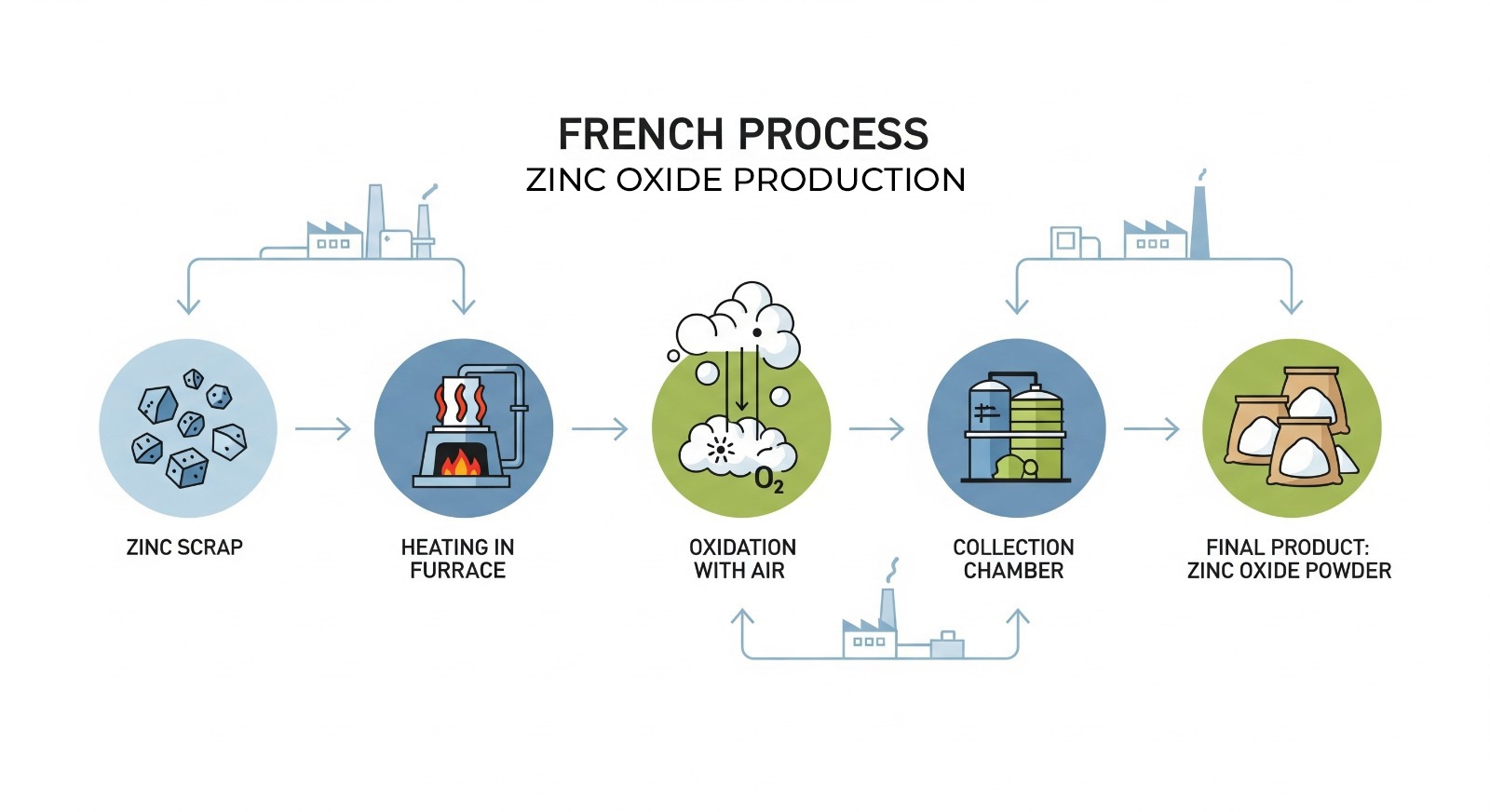

The French Process is one of the most commonly used methods to produce high-purity Zinc Oxide. In this process, Zinc Metal is oxidized in the presence of air to form Zinc Oxide. The key stages in the French process include the heating of Zinc metal to create Zinc vapor, which then reacts with oxygen to form Zinc Oxide, which is collected as a fine white powder.

The French process of producing Zinc oxide is efficient for obtaining high-purity Zinc oxide products. By utilizing Zinc scrap or Zinc metal and carefully controlling the oxidation process, manufacturers can produce Zinc oxide at various purity levels (99.5% and 99.8%) depending on the application requirements. This process also plays a role in Zinc recycling, contributing to the sustainability of Zinc as a valuable resource.

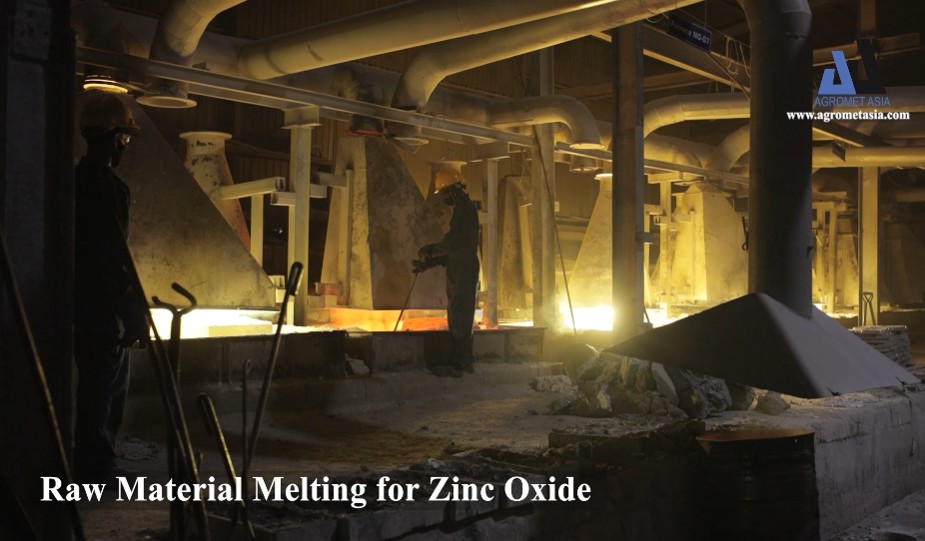

We import Zinc Dross, Zinc Skimming (from Galvanizer), Zinc Score

We manufacture Zinc Oxide by French Process using regenerative furnaces and have a 15,000 Mts capacity per annum, our product is accepted globally.

Waste Treatment

12,000 TPA

Zinc Dross and Zinc Ash

Capacity

15,000 TPA

Export Quantity

Tyre Industry

Rubber Industry

Paint Industry

Agriculture Industry

Cosmetic, Plastic, Chemical, Glass & Ceramic Industry

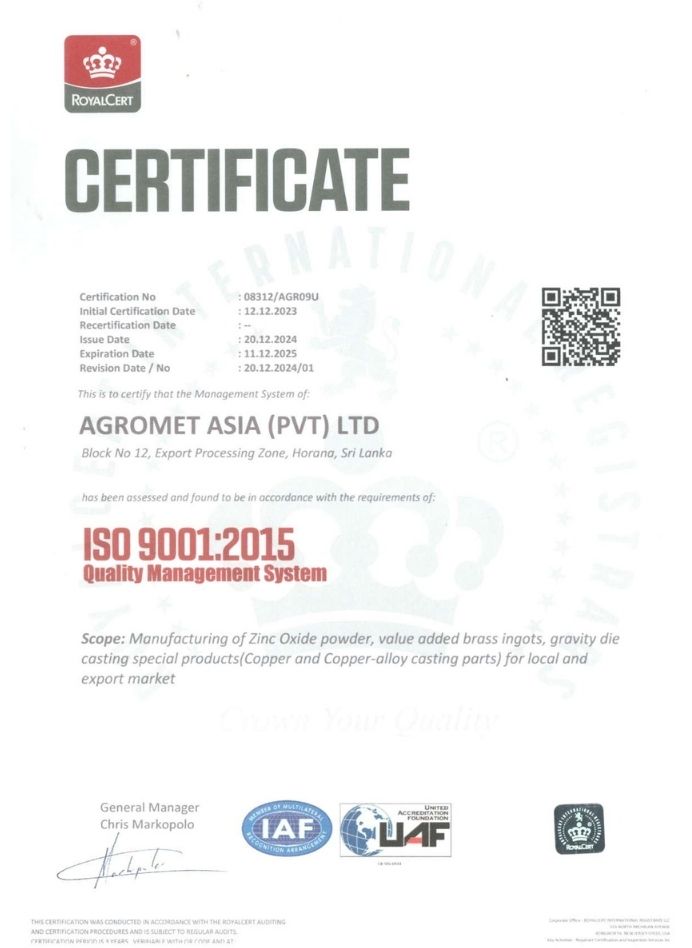

AAPL considers QUALITY as the most important ingredient in manufacturing. To achieve the highest quality, we use advanced machinery which is operated by proficient staff to ensure our quality control meets the international standards. AAPL is committed to investing in new technology and equipments to provide high-quality products for industrial applications.